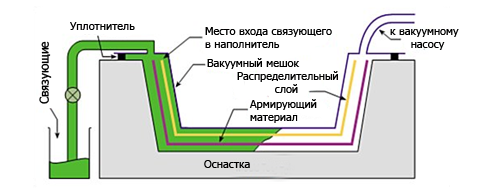

Machine for the infusion method of manufacturing composites

Vacuum infusion is a process whereby a vacuum film (bag) is created in the working cavity of the mold, and due to the difference in pressure the resin is absorbed and the reinforcing materials are impregnated.

Materials

Binder: usually polyester, epoxy. vinylester Reinforcing elements: any. It is better to use stitched materials because they have voids for faster resin flow. Fillers: any, except for honeycombs.Benefits

compared to hand molding:- best resin to fiber ratio;

- reducing the air content of the laminate;

- resin savings;

- reducing the emission of harmful substances;

- sandwich structures can be made in one step.

- less equipment costs;

- greater possibilities for varying the structure of the laminate;

- the ability to manufacture large products.

Disadvantages

- use of special binder systems with low viscosity and long pot life;

- use of a large number of consumables;

- relatively slow impregnation rate;

- high requirements for the qualification of technologists;

- high science intensity of impregnation scheme development;

- long preparatory process;

- the possibility of marriage at the initial stage.