Component mantaging shop

Includes the following equipment:

- Loader for PCB autofeed

- Stencil printer for applying solder paste on printed circuit boards

- Component installer for installing components from tape on printed circuit boards

- 8 channel convection furnace for melting solder on assembled printed circuit boards

- Visual inspection for detecting non-missing and process defects by means of visual inspection

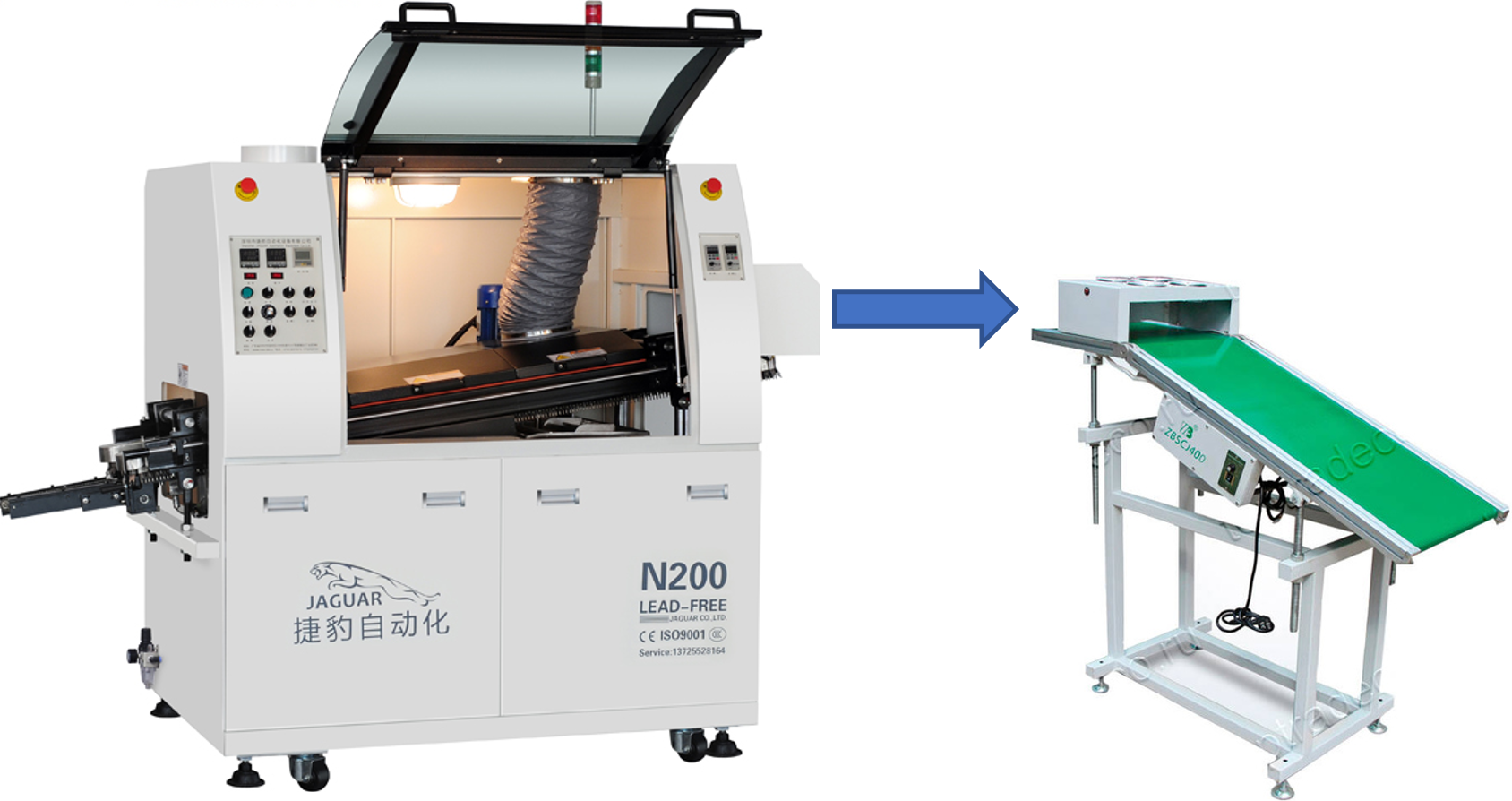

Wave soldering of components installed through the hole and surface mounting

Wave soldering performs melting and solder buildup where components are installed

This technique is used for critical products with large points and solder surfaces on components.

Manual assembly conveyor

This line provides up to 12 workplaces for conveyor assembly, both PCB assembly and PCB encapsulation. This conveyor solution is used for large batch assembly of modules and products not only in the production of electronics.